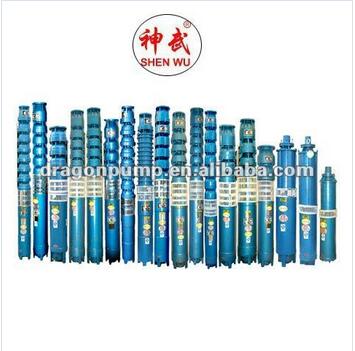

The structure of submersible water pump

Submersible pump unit consists of: pumps, submersible motors (including cable), pipes and control switch four major components. Submersible pump is single suction multi-stage vertical centrifugal pump; submersible motor is sealed water-filled wet, vertical three-phase squirrel cage induction motors, motor and pump through a single bond or a drum claw coupling directly; equipped with different specifications three-core cables; starting equipment for different capacity levels of air pressure switch and auto-pneumatic devices, pipes made of steel pipes of different diameters, flange coupling, using high-lift pump control valve.

Submersible motor shaft unit is equipped with a labyrinth of sand and two return to the oil seal assembly, to prevent the flow of sand into the motor. Submersible motor with water lubricated bearings, the lower tone laminated with rubber, pressure regulator spring, composition surge chamber, adjusting the pressure change due to temperature; motor winding polyethylene insulation, water-resistant nylon sleeve household wire, cable coupling manner technology of cable connector and the connector in insulation scrape off the paint, respectively connected, welding firm, with a layer of raw rubber around. And then wrapped with waterproof adhesive layer 2-3, 2-3 layer waterproof adhesive tape or water on the outside wrapped in a layer of rubber Inclusion (bicycle tire inside) to prevent water seepage.

Submersible pumps each stage diversion shell is provided with a rubber bearing; wheel cover is fixed to the shaft with a cone-shaped; diversion shell with screw or bolt into one. Praise Submersible Pump top with a check valve to prevent downtime caused by water hammer damage the unit. Motor closed, mouth using precision stop bolt, cable outlet add cushion seal. The upper end of the motor has a water hole, there is a bleed hole, the lower part has a drain hole. The lower portion of the motor is equipped with upper and lower thrust bearing, thrust bearing grooves for cooling, and its grinding stainless steel thrust plate to withstand the vertical axial force pump.