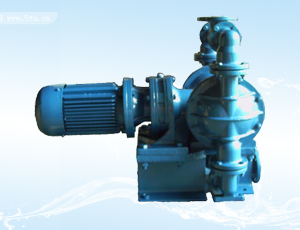

The working principle and structure of diaphragm pump

Diaphragm pump is a kind of special form in the volume pump. It is to rely on the back and forth of a diaphragm to change the volume of the studio to inhale and discharge the liquid.

The diaphragm pump mainly consists of two parts: the transmission part and the cylinder head. Driving part is driven by the driving mechanism of the diaphragm back and forth, it is the transmission form of mechanical transmission, hydraulic transmission and pneumatic transmission, etc.. Which is widely used in hydraulic transmission. Part of the diaphragm pump work mainly by the crank connecting rod mechanism, plunger, hydraulic cylinder, diaphragm, pump body, a suction valve and discharge valve and so on, which by the crankshaft, connecting rod, piston and liquid cylinder composed of drive mechanism and the reciprocating plunger pump is very similar.

Diaphragm pump at work, crank connecting rod mechanism driven by the motor, drive the plunger reciprocating motion, the movement of the plunger through the hydraulic cylinder in the working fluid (oil, and spread to the diaphragm to diaphragm back and forth agitation.

Diaphragm pump cylinder head mainly consists of a diaphragm to be transported in the liquid and liquid separation, when the diaphragm to move toward the side of the transmission mechanism, pump cylinder in the studio for negative pressure inhalation liquid; when the diaphragm to the other side of the movement, the discharge of liquid. Is transported liquid in the pump cylinder is diaphragm and working liquid separated, only with the pump cylinder, a suction valve and a discharge valve and diaphragm pump side contact without touching the plunger and sealing device, which makes the plunger important parts in oil medium work in good working condition.

Diaphragm to have good flexibility, but also has a better corrosion resistance, usually with PTFE, rubber and other materials. Diaphragm two pan bottom shape parts with mesh is to prevent the diaphragm locally produced large deformation and settings, generally called the limiter for diaphragm. The sealing performance of the diaphragm pump is good, and can be easily reached without leakage, and can be used for transporting acid, alkali, salt and other corrosive liquids and high viscosity liquids.