1. Instrument wind line blocking. Because the valve throttle effect in wind instrument branch line, the wind line where the stolen goods blocked accumulation. The instrument air pressure is too low, can not fully open valve fully closed, even the valve does not move.

2. Air filter pressure relief valve failure. Air filter relief pressure valve used for a long time the booty too much, valve leakage, valve set pressure output end, the output of the instrumentation wind pressure is less than the required pressure. The regulating valve is slow, can not fully open or fully closed operation

3. Copper pipe connection failure. Copper tube aging, the air leakage of the joint is connected with a loose or stolen goods blocked tubes enable signal meter, low air pressure, resulting in the adjustment valve does not move, can not be fully opened and fully closed, the manual valve bit unstable produced to regulate the oscillation.

4. Instrument wind system fault. Air pressure station anomalies, the purification device abnormal air tank, water cut not timely, the wind line icing, instrument air line leakage or be stolen goods blocked, resulting in instrument air pressure is too low or no wind.

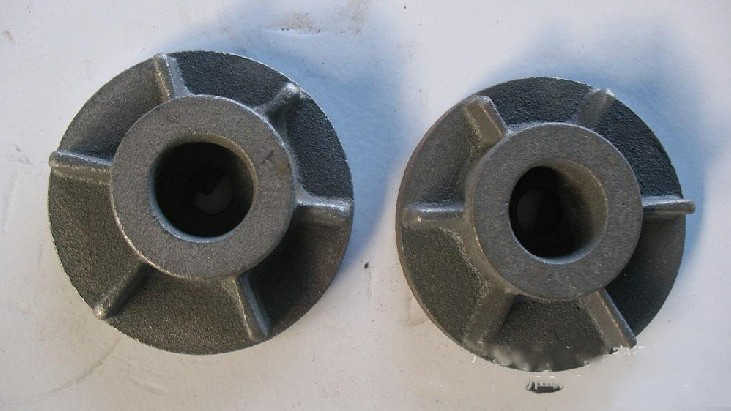

5. Instrument air branch valve

No, cause the valve does not move. Often occurs in the device overhaul, after the transformation of the car.