1. Floating ball valve

Ball valve ball is floating in the medium pressure, the ball can produce a certain displacement and pressure in the export side of the sealing surface, to ensure that the export side seal.

Floating ball valve structure is simple, good sealing, but the ball under the load of working medium to pass all the export ring, so to consider sealing ring material can withstand the work load of the media sphere, due to the impact of high pressure, the ball may shift can occur. This structure is generally used for medium and low pressure ball valves.

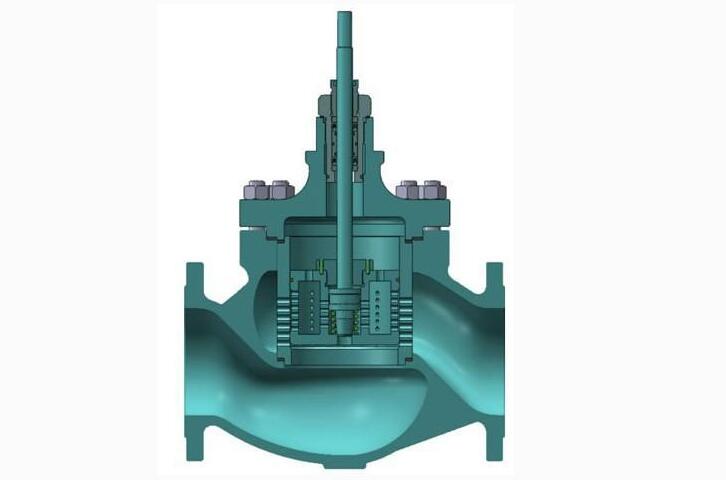

2. Fball valve

Ball of the ball is fixed, does not produce movement after compression. Fixed ball valve with a floating seat, by the media pressure, the valve seat to move, so that the sealing ring on the ball, in order to ensure that the seal. Usually with the ball in the upper and lower shaft with bearings, operating torque, suitable for high pressure and large diameter of the valve.

In order to reduce the valve operating torque and increase the reliability of the seal, in recent years and the emergence of the valve seal, both in the sealing surface pressure injection of a special lubricant, to form a layer of film that enhances the sealing, and reduce operating torque, more suitable for large-diameter high-pressure ball valve.

3. Elastic ball ball valve (that is, the track ball valve)

Ball valve of the ball is elastic. Sphere and valve seat ring are made of metal materials, sealing pressure is very large, depending on the pressure of the medium itself has reached less than the requirements of the seal must be applied. This valve is suitable for high temperature and high pressure medium.

An elastic ball is provided with an elastic groove at the lower end of the inner wall of the ball. When the channel is closed, the ball is opened and the valve seat is pressed to seal by the wedge head of the valve rod. Before turning the ball to loosen the wedge head, the ball will be restored to the original shape, so that a small gap between the ball and the seat, you can reduce the friction of the sealing surface and operating torque.

4. V type ball valve

The ball valve is fixed ball valve, ball valve seal is a single seat, regulation performance is the ball in the best, the flow characteristics is the percentage of, can adjust the ratio of 100:1. It has a shear effect between the V type incision and metal seat, especially suitable for fiber, micro solid particles, slurry and other media.

5. Three way ball valve

Three way ball valve has T type and L type. T type can make the three orthogonal channels and cut off the third channels Unicom, from the diversion, the confluence of the role. Type L can only connect the two orthogonal channels, can not be maintained at the same time the third channels of mutual communication, only play the role of distribution.