Electric regulating valve in the processing or assembling received the influence of process, may cause electric regulating valve inner leakage, main problems or in the limit switch, mainly because of the limit switch action compared with that of the fixed due to medium valve control at run time of regulating valve of continuous scouring and mode, will cause the valve does not close and lead to leakage was found in the problem. The main problem is to adjust the position of the limit switch, you can solve the problem.

There are other problems:

1. Adjust the valve in the wrong cause of the internal leakage.

2. Due to the electric control valve in the control part of the failure. Mainly because of the electric control valve in the valve limit switch, over torque switch and so on because, above also has the certain introduction. Because of these problems will cause the sealing surface wear or corrosion: mainly in trachoma occurs pitting scratches and, which is caused by the internal leakage problem. The emergence of such a problem is mainly in the effort to adjust the up and down.

3. Because the electric actuator zero setting is not accurate, this is causes the valve can not be closed. Main adjustment method: manual shutdown valve, or manually shut the valve and so on, do not know in the back half circle, this to adjust the adjustment limit.

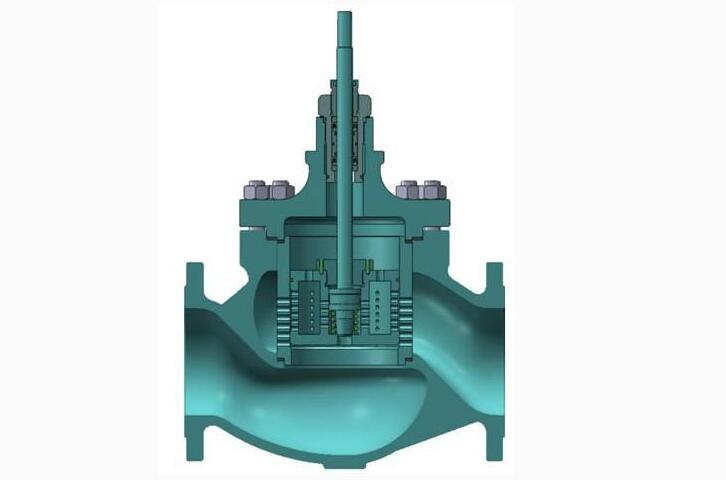

4. The valve is under the push off type, if the actuator is not large enough, it will lead to the valve can not be fully closed, which is one of the main problems of internal leakage. Solution: the replacement of the major thrust of the actuator, or the balance of the spool to reduce the imbalance force.